Testing instrument

1.X-ray stress analyzer is used to measure the residual stress in bearing ring and roller materials and the content of residual austenite in materials

X-ray stress analyzer

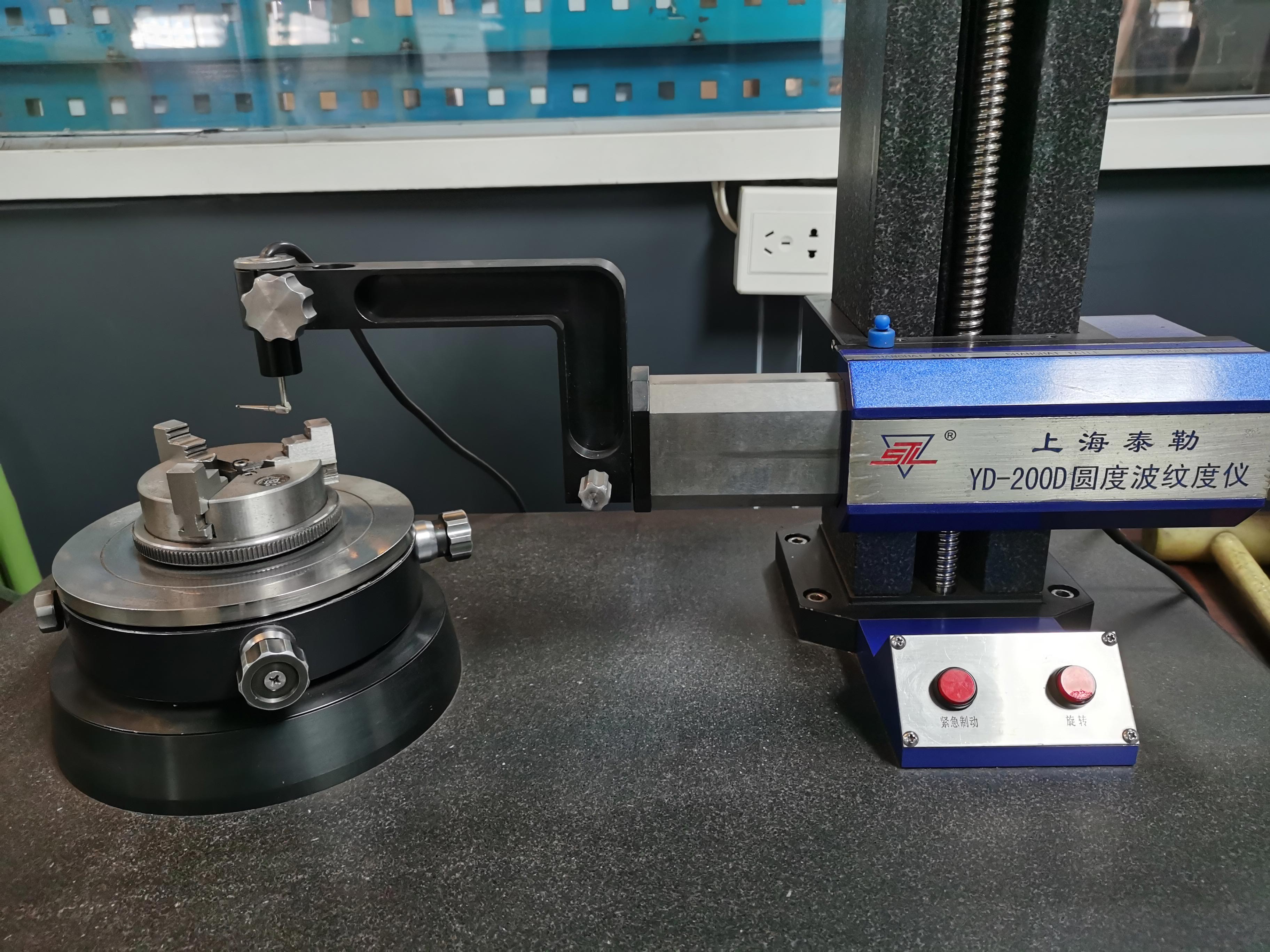

X-ray stress analyzer2.CS3000A carbon sulfur high-speed analyzer can quantitatively analyze the two non-metallic elements of carbon and sulfur in steel, accurately measure the percentage content of carbon and sulfur in steel and other materials, and conduct material acceptance conveniently and quickly.

CS3000A carbon sulfur high speed analyzer

CS3000A carbon sulfur high speed analyzer3.Dm6 m LIBS electron metallographic microscope to determine the microstructure and microstructure of the material.

Dm6 m LIBS Electron Metallographic Microscope

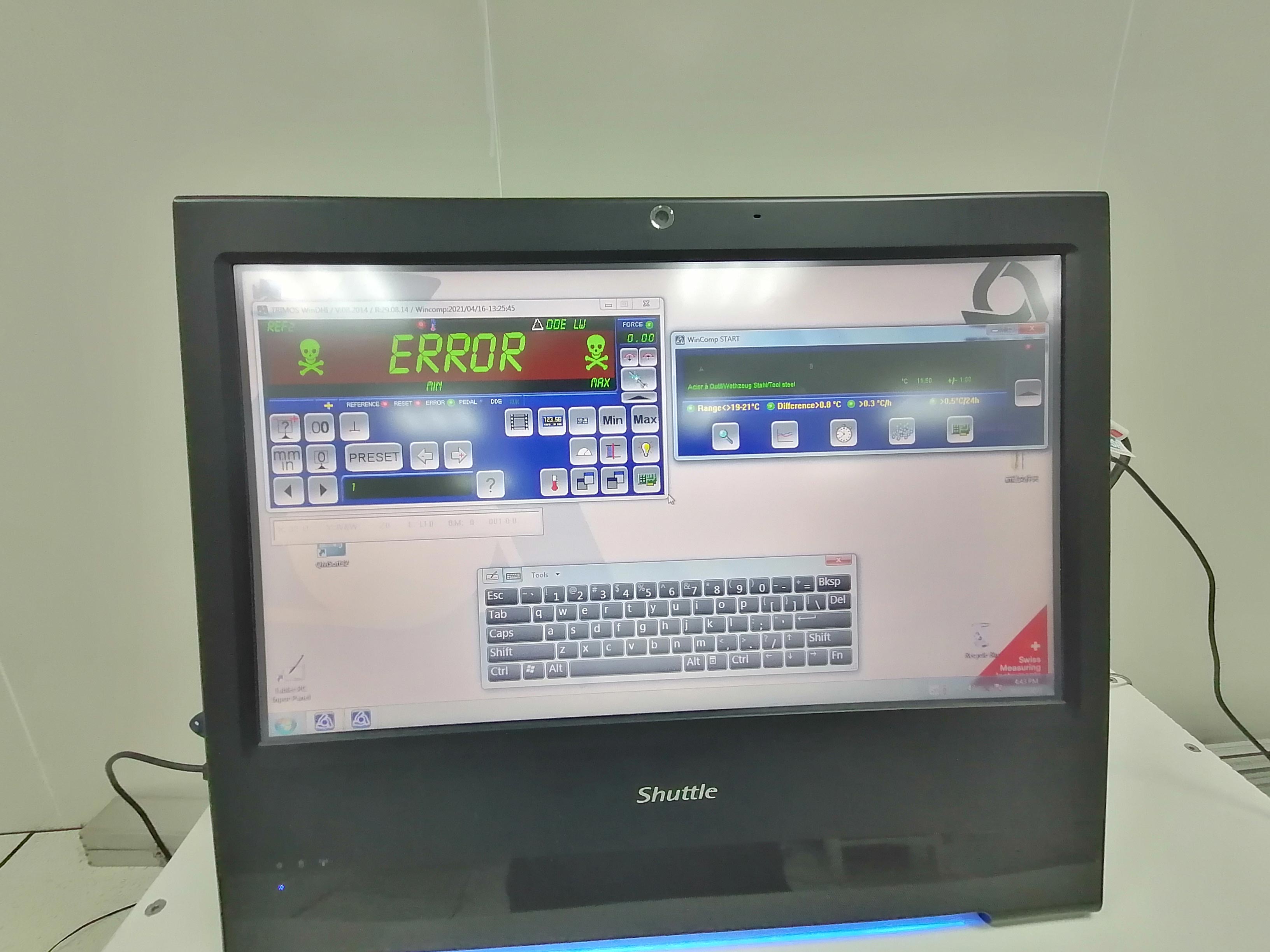

Dm6 m LIBS Electron Metallographic Microscope4.Digital display Rockwell hardness tester 200hrs-150 to measure the hardness of bearing rings and rollers after quenching.

Digital Rockwell hardness tester 200hrs-150

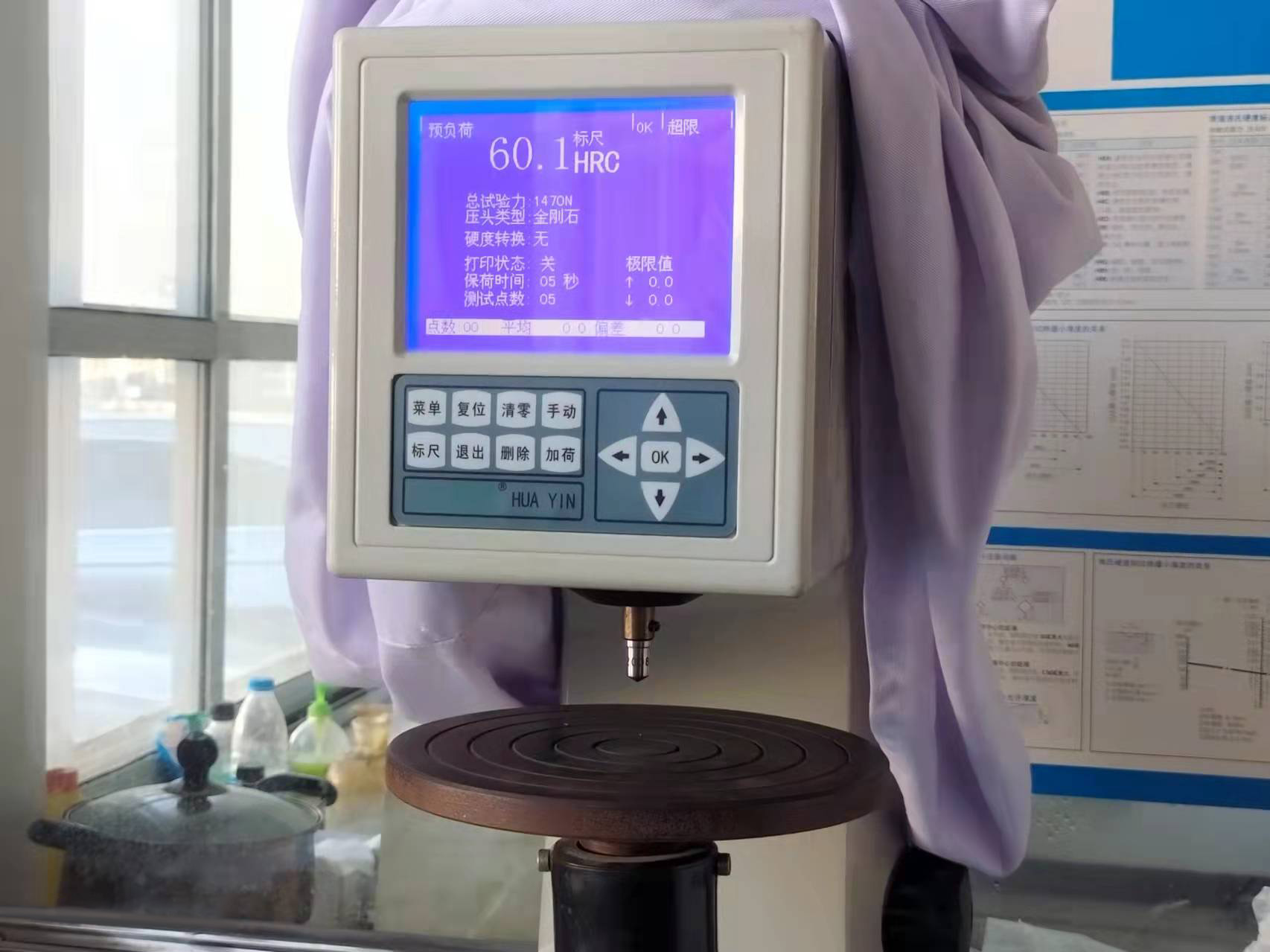

Digital Rockwell hardness tester 200hrs-1505.YD-200D roundness and waviness instrument is used to measure the roundness and waviness of ferrule and roller.

YD-200D roundness and waviness instrument

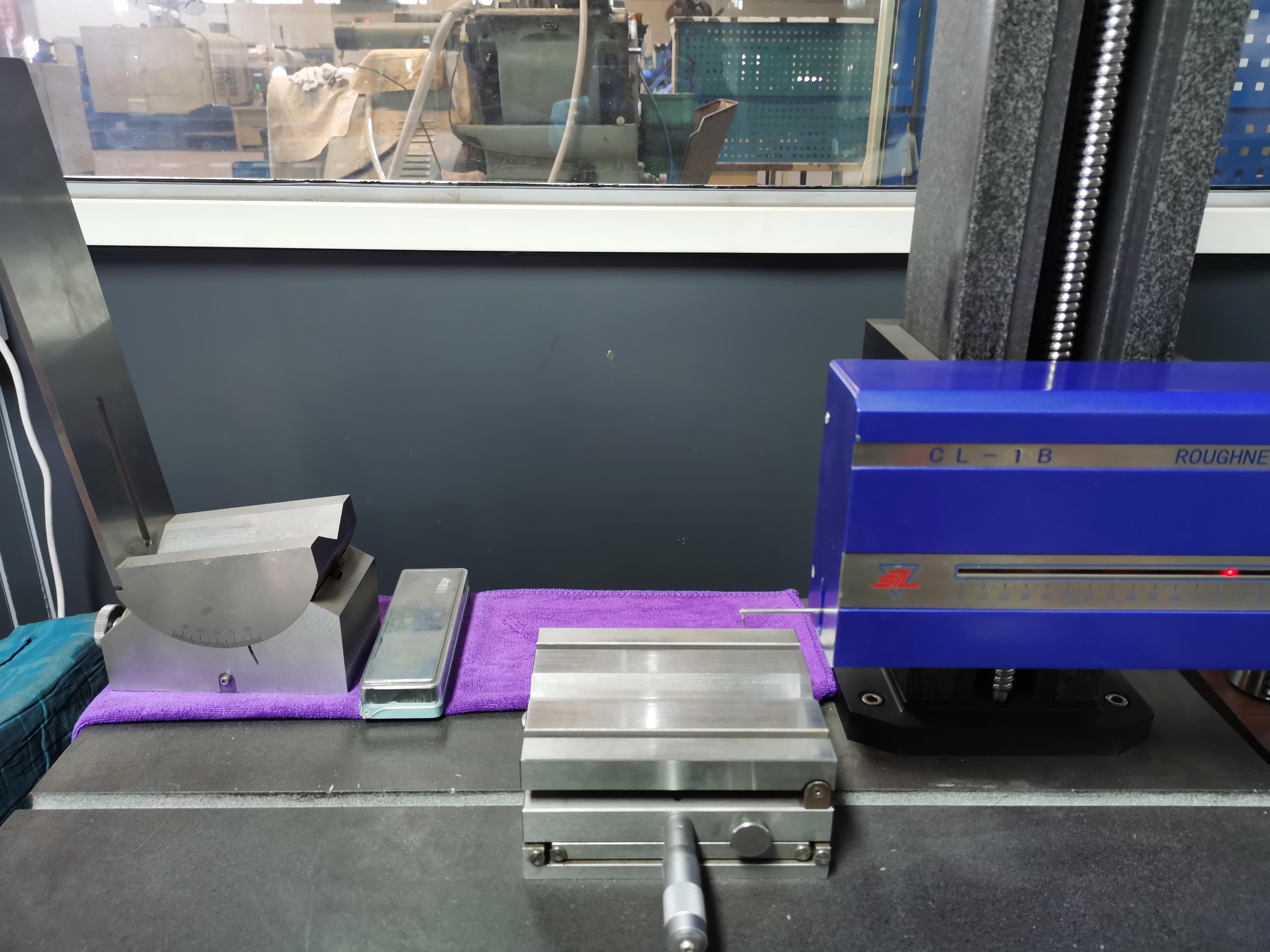

YD-200D roundness and waviness instrument6.Cl-1B profilometer to measure the contour and roughness of ferrule and roller.

Cl-1B profiler

Cl-1B profiler7.JD9A precision length measuring instrument is used to measure the actual size of inner diameter and outer diameter and identify the sample ring.

JD9A precision length measuring instrument

JD9A precision length measuring instrument8.German Zeiss accura CMM can accurately carry out three-dimensional measurement. Professional Ruby probe can measure the spatial dimension of bearing parts, the geometric tolerance and dimensional tolerance of bearing parts, and the shape and contour error of ferrule raceway.

Zeiss accura CMM

Zeiss accura CMM